Introduction

Servo is a type of geared motor that can only rotate 180 degrees. It is controlled by sending electrical pulses from your board. These pulses tell the servo what position it should move to.

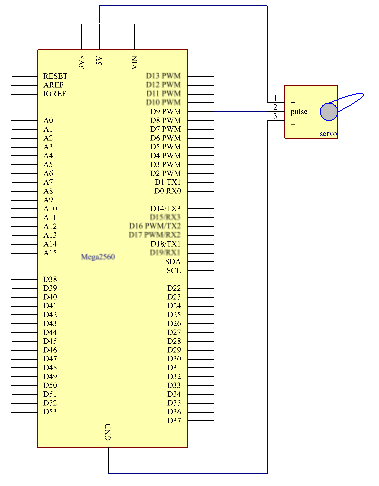

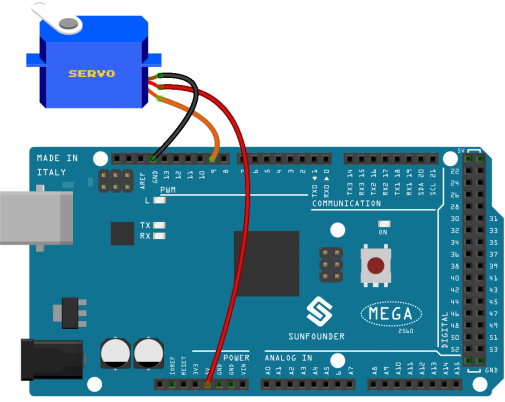

A servo has three wires: the brown wire is GND, the red one is VCC, and the orange one is signal line.

Components

Experimental Principle

Servo

A servo is generally composed of the following parts: case, shaft, gear train, adjustable potentiometer, DC motor, and control circuit board.

It works like this: The Mega 2560 board sends out PWM signals to the servo, and then the control circuit in the servo receives the signals through the signal pin and controls the motor inside to turn. As a result, the motor drives the gear chain and then motivates the shaft after deceleration. The shaft and adjustable potentiometer of the servo are connected together. When the shaft rotates, it drives the pot, so the pot outputs a voltage signal to the circuit board. Then the board determines the direction and speed of rotation based on the current position, so it can stop exactly at the right position as defined and hold there.

The schematic diagram:

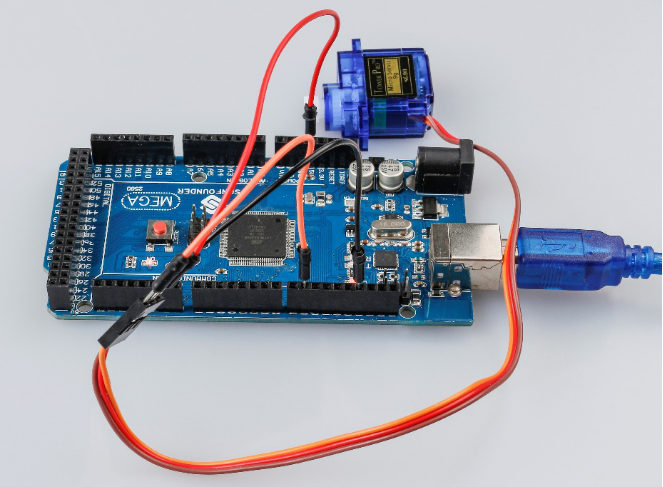

Experimental Procedures

Step 1: Build the circuit (Brown to GND, Red to VCC, Orange to pin 9 of the control board)

Step 2: Open the code file.

Step 3: Select the Board and Port.

Step 4: Upload the sketch to the board.

Now, you can see the rocker arm of the servo rotate and stop at 90 degrees (15 degrees each time). And then it rotates in the opposite direction.

Code Analysis

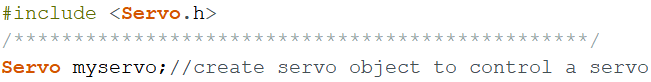

Code Analysis 12-1 Include a library

With the Servo.h file included, you can call the functions in this file later. Servo is a built-in library in the Arduino IDE. You can find the Servo folder under the installation path C:\Program Files\Arduino\libraries.

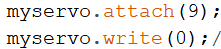

Code Analysis 12-2 Initialize the servo

myservo.attach(): Attach the Servo variable to a pin. Initialize the servo attach to pin9.

myservo.write(): Writes a value to the servo, controlling the shaft accordingly. On a standard servo, this will set the angle of the shaft (in degrees), moving the shaft to that orientation. Here let the servo stay in the 0 angle firstly.

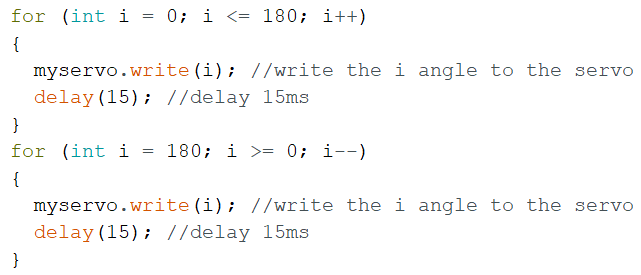

Code Analysis 12-3 Servo rotate

.

.

.

Use 2 for() statement to write 0 – 180 to the servo, so that you can see the servo rotate from 0 to 180 angle,then turn back to 0.